Hunufa đã chuyển sang website mới tại https://hunufa.vn/ từ ngày 01/01/2024. Dữ liệu trên Hunufa.com hiện không còn được cập nhật.

In the current F&B industry. The printing of plastic cups to popularize, spread, and market the brand to customers is indispensable.

But whether with the current state of mass printing. So do you really understand about Cup Printing, the brand and are you ensuring food safety for your brand?

As one of the units specializing in providing disposable products, Hunufa understands the needs of customers, in addition, Hunufa will show you whether you are correctly understanding and ensuring the safety and hygiene for yourself. Your brand.

Handmade cup printing (Silkscreen printing)

Silkscreen printing is a form of printing in which the mesh plate of the printing mold is made of silk. Later, when the silk screen could be replaced by other materials such as cotton fabric, chemical fiber fabric, metal mesh to make, the name was expanded as mesh printing.

Strengths: Flexibility to print in small quantities.

Weaknesses: can print in 1 color, must have a drying process, easy to smear ink, can't synchronize the product, in addition, it is easy to have a slight odor after the finished product, so most of them cannot achieve food hygiene and safety.

Currently, most printing units are applying manual cup printing. But most customers still do not know that their products are up to the standards of food hygiene and safety?

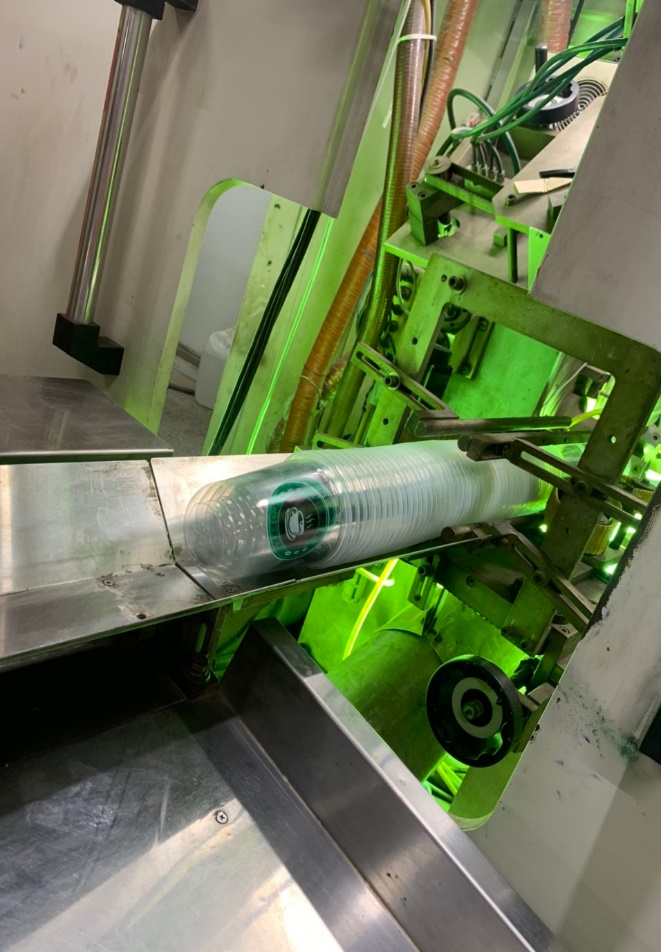

Automatic cup printing

With higher investment cost in machinery than manual printing. Therefore, automatic printing products will be more technologically and synchronous. In addition, maximum production speed and food safety are also achieved.

Outstanding advantages of automatic printing:

Print multiple colors at once

Agree on model

Safe water-based ink

Closed process ensures food safety and hygiene

Ensure printing progress, save time

CONTACT HOTLINE 1900 0040

CONSULTING BUYING TODAY TO ENJOY THE BEST PRICE!

: 31/05/2023

: 13/05/2023

: 14/04/2023

: 14/01/2023

: 10/11/2022